Fulfillment is not a topic that online stores find very pleasant.

However, logistics in an e-commerce business plays a key role. Fulfillment is the key to a successful strategy.

The fulfillment process can make or break the trust a consumer has in an e-commerce business. In fact, if you look closely, the most successful online companies, such as Amazon, have one thing in common: a smart fulfillment strategy.

In this article, we will provide you with little information on what exactly fulfillment is, what processes it consists of, what types of fulfillment you can adopt, the challenges you may encounter during the process, and finally three useful tips for a successful fulfillment strategy.

WHAT IS FULFILLMENT?

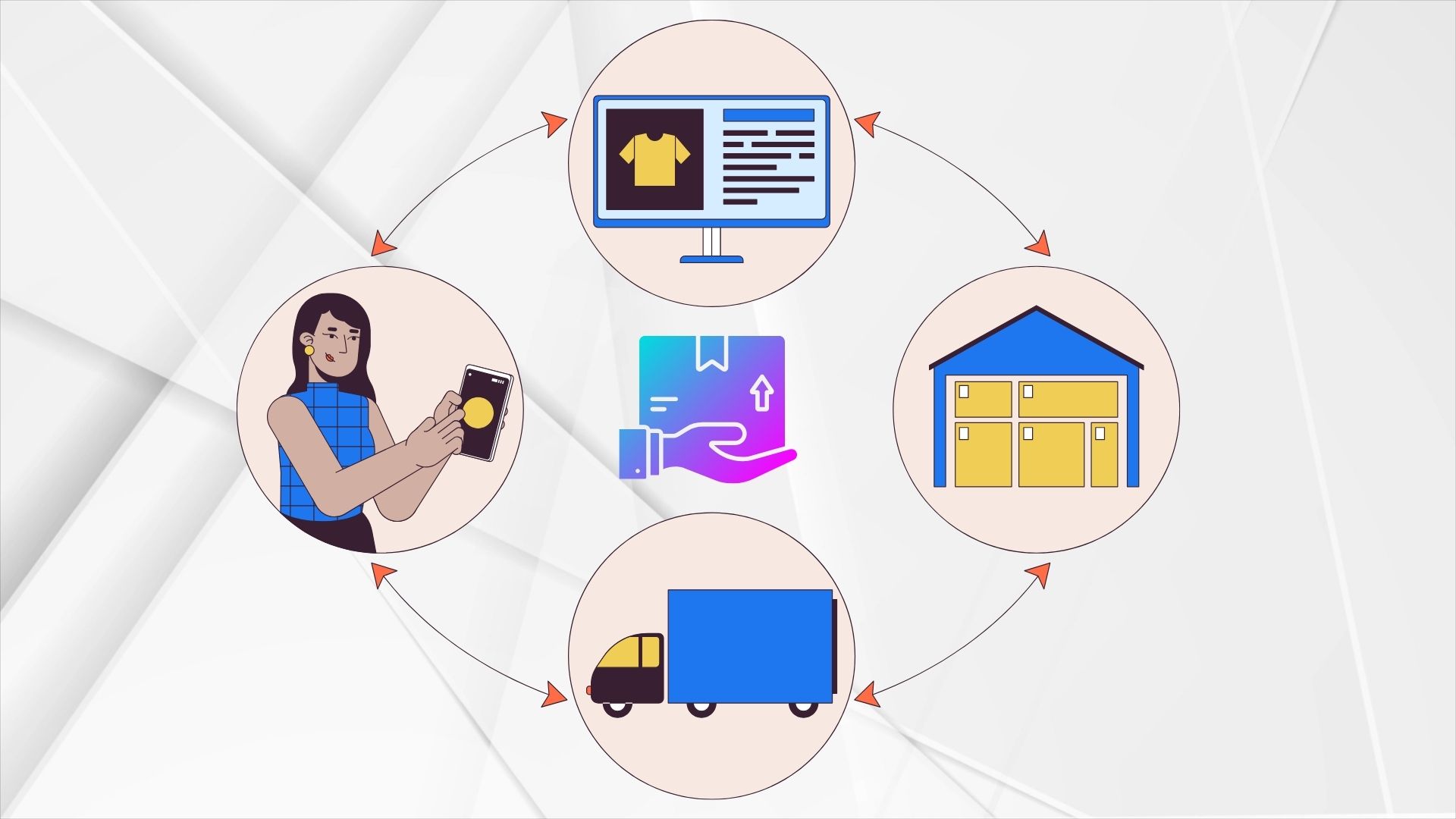

The term Fulfillment is used to describe the process of order processing in e-commerce. In other words, the entire process from ordering a product to delivery to the end customer. As such, fulfillment often includes post-processing and returns management.

Most e-commerce sellers perform order fulfillment themselves or outsource some of the steps.

Contrary to popular belief, shipping and fulfillment do not refer to the same activity. In fact, fulfillment encompasses the entire process. Shipping is an indispensable component of fulfillment, but the two terms are not overlapping.

THE MOST IMPORTANT STEPS IN THE FULFILLMENT PROCESS

As mentioned earlier, fulfillment is that process through which customers receive their products after placing an order. There are several steps in the order fulfillment process. Knowing each of these steps can help you have a more successful e-commerce business.

The fulfillment process can be divided into eight stages:

- Receiving inventory:

Goods may come from a third party, another business department or warehouse; or in a variety of forms from other external or internal sources.

In all cases, incoming inventory must be counted, inspected, and inventoried to ensure that the correct quantity has been received and that the quality is acceptable. SKUs or bar codes on incoming products are used in the receiving and storage processes, and, later, to retrieve goods from internal storage.

- Repository management:

After receiving inventory, it is necessary to organize and store products in the warehouse. Stock organization plays a key role in the order fulfillment system because it determines the speed and accuracy of the process. It is advisable to place products according to their popularity, with the best-selling items placed closer to the packing counter.

- Order processing:

An order processing management system dictates product picking and packing activities for each new order received from the customer. In e-commerce, the order management software should be integrated with the shopping cart to automatically initiate order processing.

- Order withdrawal:

A picking team or robots in an automated warehouse select items from the warehouse based on the instructions of a packing slip. The packing slip contains specific information, such as a list of item SKUs, product colors, sizes, unit numbers, and product location in the distribution center warehouse.

- Packaging:

A packing team will collect the items for the order and pack them in appropriately sized envelopes and boxes.

During this phase, one should aim to pack goods with the lowest possible dimensional weight, so that more items can be loaded into delivery trucks both to reduce shipping costs and speed up transportation time, and for less environmental impact.

In addition, return labels and receipts should be included in the package for customer convenience.

- Shipping:

After packing the goods, they must be sent to a shipping courier.

Business owners should be aware that each courier company has its own packaging requirements and shipping costs for weight. Management teams must ensure that shipping standards are met so that there are no delays in delivery

- Delivery:

Finally, the goods are delivered to the customer. Companies must send a shipping confirmation to the buyer’s e-mail to inform them of their incoming package.

Very important for an e-commerce is to receive feedback regarding product quality, shipping, and wait times. This will help identify any inefficiencies in the order fulfillment process and whether and improvements can be made in their handling.

- Processing Returns:

In the event that a customer is not satisfied and wishes to return their order, they must return the items with a return label. Employees must then inspect the goods and process a refund.

If the product malfunctions, it should be properly discarded or recycled.

WHAT ARE THE FULFILLMENT MODELS?

There are four fulfillment models to choose from: in-house, outsourcing, drop shipping, and hybrid. Each model meets specific business needs.

Let’s look at them in detail.

- IN-HOUSE FULFILLMENT

In the in-house order fulfillment model, a company uses its own employees to manage the fulfillment processes. Employees manage all phases of the fulfillment process, including storing and shipping products on-site at a location controlled by the company. In-house fulfillment is ideal for established companies that want to have end-to-end control over the entire operation. Some startups are beginning to use in-house fulfillment as a low-cost option, particularly those with small order volumes. When they exceed 100-150 monthly orders, many switch to outsourced or hybrid fulfillment models.

- OUTSOURCED FULFILLMENT

Outsourced order fulfillment is when shipping, warehousing, and order/reimbursement processing are handled by a third-party logistics company (called 3PL – Third Party Logistic). Companies that do not have sufficient storage space or staff may choose this option. In this case, 3PL employees manage the entire fulfillment process, from receiving inventory from manufacturers to delivering orders to the end customer. The inventory is stored in a warehouse controlled by the 3PL, which means that companies using outsourced fulfillment do not need to invest in their own facilities.

- DROPSHIPPING

The order is produced and shipped by the manufacturer. From a pro perspective, this lowers the barrier to entry and minimizes overhead costs, which is key for startups and e-commerce companies. It also eliminates the middleman, which can potentially save the buyer money. On the cons side, it can also take control away from merchants, particularly in terms of inventory management and order fulfillment. It can also significantly delay shipments to customers because many manufacturers are in other countries, far from the merchant’s customer base. In this case, shipping can take longer and cost more.

- HYBRID FULFILLMENT

A hybrid model simply means a combination of two or more of the three models above. For example, a company may choose to handle order fulfillment of all or only the most popular products in-house, but also choose to outsource fulfillment during peak periods, such as vacations, and ship large and bulky items directly from the manufacturer.

FULFILLMENT: THE CHALLENGES YOU MAY FACE

Inventory stocks exhausted:

There are possibilities of running out of inventory during order fulfillment operations. Therefore, it is mandatory to have advanced inventory management systems in place to notify you of approaching inventory depletion.

Seamless distribution:

If the company does not have an extensive fleet of couriers , it will not be able to handle the delivery smoothly. Therefore, one should opt to outsource logistics with providers such as FBY which can simplify the order fulfillment process and provide efficient logistical distribution for smooth delivery.

HOW TO DEVISE A SUCCESSFUL FULFILLMENT STRATEGY? 3 USEFUL TIPS

It can be difficult to devise a successful strategy that takes into account all the elements that make up the fulfillment process. You must first be aware of all aspects of your supply chain and then work around them to provide a superior experience for your customer.

Here are some tips to start drafting an order fulfillment strategy that can help you deliver products on time and also improve customer satisfaction.

Keep regular track of inventory

Inventory is the most critical area when it comes to order fulfillment. The whole chain depends on it. Therefore, inventory must remain a focal point. You need to adopt an inventory management system that can help you get a real-time cycle count so that you are always aware when a product is out of stock or unavailable.

Without real-time inventory management, it is not possible to keep the warehouse organized accurately.

Automating the warehouse

Technology has taken over every aspect of the fulfillment chain. Even the warehouse should not be left behind.

You can choose to automate the warehouse with technologies including RFID identification, or IoT for easier tracking and barcodes.

This will reduce manual errors and process orders much faster.

Maintaining a transparent supply chain

A thorough understanding of the Supply Chain allows one to know and improve the areas that are not working well; by learning, thus, to identify the deficient areas one will be able to remedy the problem quickly.

Therefore, it is very important to continuously monitor the supply chain and collect data.

CONCLUSION

Anyone involved in e-commerce knows the role that logistics plays. More and more companies have realized that this process is more than a necessary evil. Rather, fulfillment in e-commerce is one of the most important pillars of good long-term performance through consumer focus. For many online entrepreneurs, outsourcing this area and working with companies that specialize in logistics services is the best solution. In addition to their network and volume advantages, they are often the best solution for online stores because of their expertise, experience, and efficient workflows.